Conveyor System Technology

For all conveyor technology product solutions, we focus on safety, operability and durability. We help you get things moving.

Individual conveying and bulk material technology

Tailor-made support concepts are created at Werkstätten GmbH in close cooperation with our customers. In the same way that we think during the planning process, we also act the same during the implementation: quickly, conscientiously and goal-oriented. We implement the right solutions based on the requirements of the conveyed medium, the transport routes, the necessary functions and the special features of the object. No detail goes unnoticed, no matter how small it may seem at first glance. We prefer to check one time too many than one too few and regard every project as a chance to prove ourselves personally.

Made to measure solutions

Conveyor systems manufactured by us enable the gentle transport of bulk materials such as dust, granulate, powder and sludge in any desired direction — whether vertically, perpendicular or on inclines. More energy efficiency, greater safety and less time wasted are just some of the different issues that customers turn to us with. Our answer is always an innovative, tailor-made system that fits exactly. From low-budget to high-end, we implement customised system solutions in the field of conveyor technology in a targeted manner. That’s our goal.

Made to measure solutions

Conveyor systems manufactured by us enable the gentle transport of bulk materials such as dust, granulate, powder and sludge in any desired direction — whether vertically, perpendicular or on inclines. More energy efficiency, greater safety and less time wasted are just some of the different issues that customers turn to us with. Our answer is always an innovative, tailor-made system that fits exactly. From low-budget to high-end, we implement customised system solutions in the field of conveyor technology in a targeted manner. That’s our goal.

Customised production – Made in Germany.

We draw on expertise that has grown over decades. State-of-the-art development, production and testing facilities are available.

Customised production – Made in Germany.

We draw on expertise that has grown over decades. State-of-the-art development, production and testing facilities are available.

Our product range

Transport-mechanical conveying

- Trough screws

- Tubular screws, tubular screw conveyors

- Twin screws

- Vertical conveyor

- Elevators / bucket elevators

- Belt conveyor

Process screws

- Metering screws

- Fine dosing screws

- Weighing screws

- Mixing screws

- Damping screws

- Double-shaft mixers

- Cooling screws with cooling jacket and complete internal cooling of the screw shaft and screw flights

- Heating screws with heating jacket and complete internal heating of the screw shaft and screw flights

Filling / emptying

- Big-Bag filling stations

- Big-Bag emptying stations

- Rotary valves

- Flat slide valves

- Interchangeable flaps

- Versions & approvals

- Standard components & additional functions

- Advantages

- Areas of application

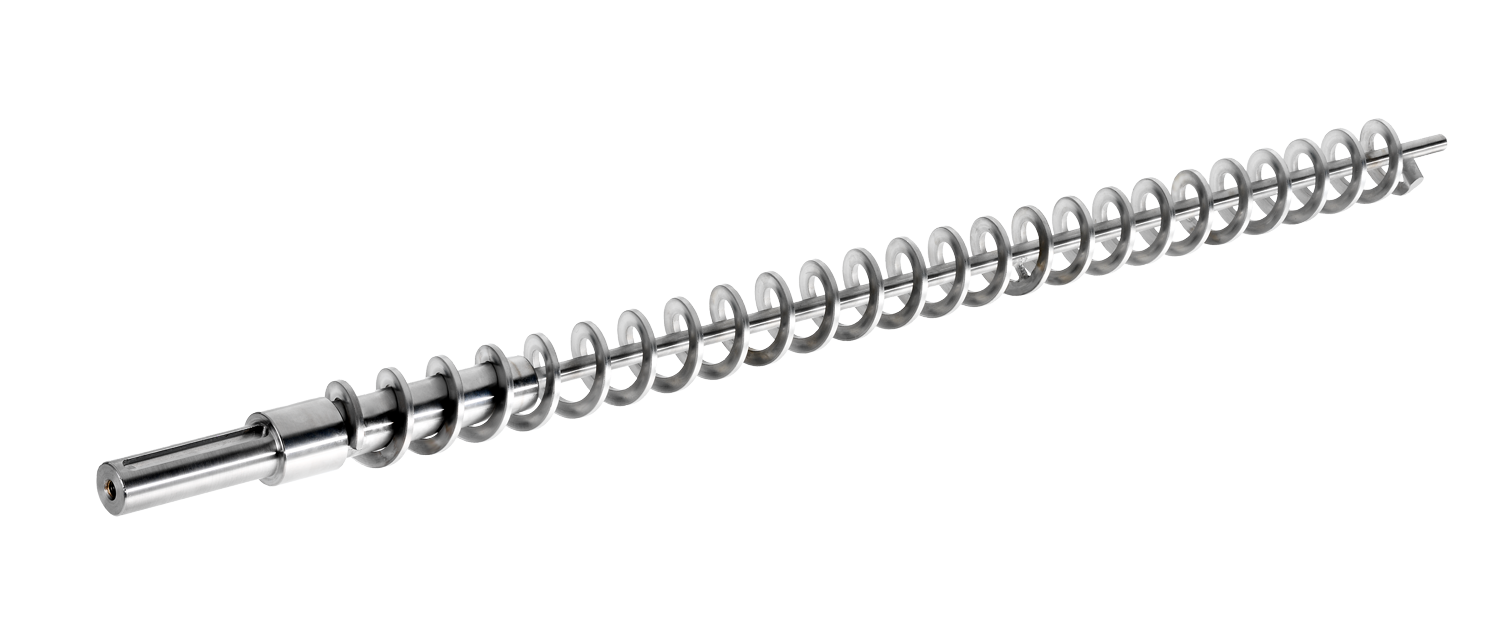

- Solid blade screws, belt screws, paddle screws, spiral conveyors

- Food-grade

- Dust-tight, gas-tight, pressure-tight

- ATEX-compliant pressure shock resistant design

- Variable diameters, lengths and delivery rates

- Horizontal or ascending arrangement

- Special materials

- Wear resistant design

- Multiple inlets and outlets

- Insulation

- Movable

- Temperable versions

- Full detector

- Centre bearing

- Safety switch

- Speed monitor

- Cleaning and inspection openings

- Shaft sealing: Stuffing box, mechanical seal

- Gear types: Spur gears, parallel shaft gears and bevel gears

- Drive types: Direct drive, chain drive and clutch drive

- Flange or pedestal bearing

- Hardfacing

- Replaceable wear protection for the screw trough segment by segment

- CIP cleaning

- Material slide valve — gate valve

- Replaceable perforated sieve

Your advantages at a glance

- Extensive equipment options

- Low susceptibility to interference

- Long lifespan

- Low noise level

- High energy efficiency

- Quick availability of spare parts

- Quick and easy assembly

- Maintenance friendly construction

- Wide application range

- Available in a wide range of materials

Our products are used in the following industries:

- Food industry

- Starch industry

- Chemical industry

- Sewage treatment plants / sludge dewatering

- Oil industry

- Concrete industry

and many other industries and companies where the handling of bulk material plays an important role

Service

Assembly & Commissioning

An integral part of the large workshop team are experienced and skilled employees who carry out the assembly of products manufactured by us as well as third-party products. We put everything together that belongs together.

Repair & Maintenance

We offer our customers worldwide fast maintenance and repair when required. As an experienced company with technically skilled employees, we solve problems reliably, competently and at fair market prices.

Examples from our product portfolio

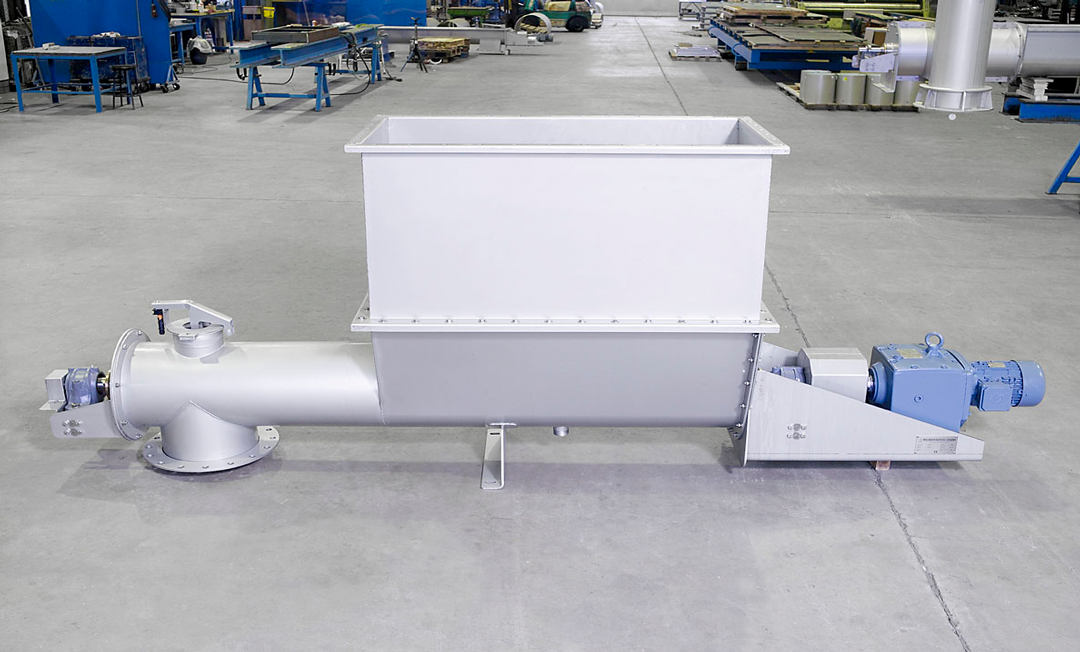

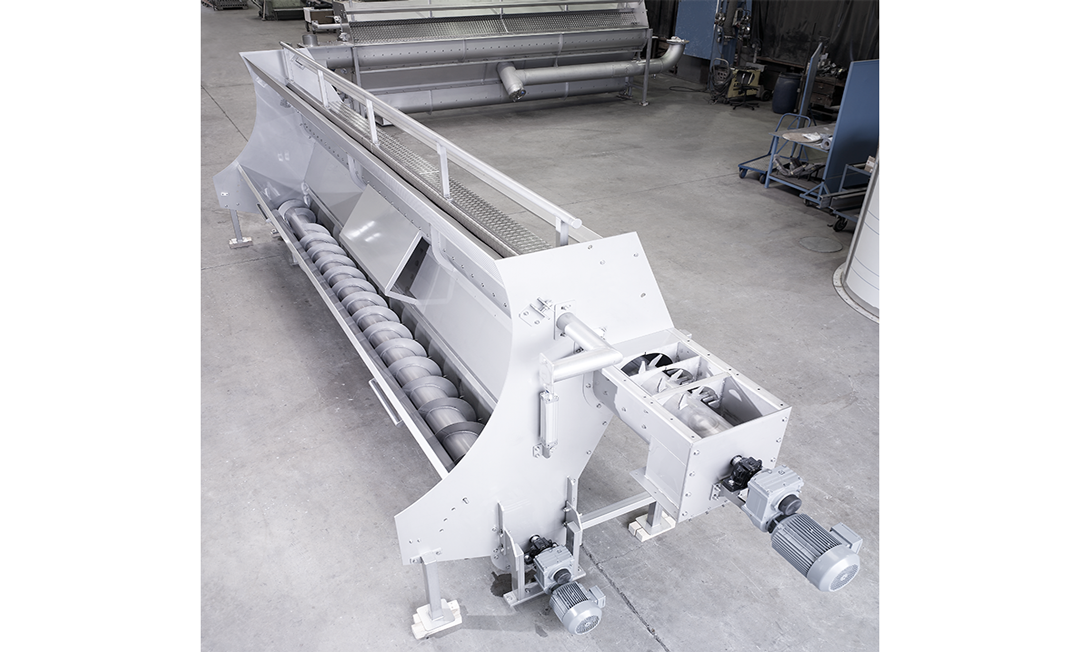

Screw conveyors

Precise transport, exact dosing and easy operation. We develop low-maintenance screw conveyors precisely matched to respective product properties, working conditions and tasks.

Trough screw conveyor: For transport on slopes of up to 30 degrees.

Tubular screw conveyor: For transport on slopes of more than 30 degrees.

Your advantages at a glance

- Conveying of powder, granules,

- Dust, sludge and problematic goods

- Shaft geometry adapted to bulk material

- Can be absolutely dustproof, shockproof and gas-tight

- Modular design

- Extremely flexible and suitable for reversing the direction of drive rotation

Vertical conveyors

These travel steeply upwards. Our dust-tight vertical conveyors reliably ensure the vertical transport of bulk material. They can be used for many purposes and different products, require minimal space and can be integrated into existing systems. We supply customised solutions, also in food-safe versions.

Your advantages at a glance

- High capacity

- Low space requirement

- Can overcome large differences in height

- Can be integrated into existing systems

- Dust-tight

- Bearing outside the conveyed material

- Design of the inlet and outlet opening in all directions

- Low height loss for input and output unit

- Inspection flaps / cleaning flaps

- ATEX-compliant version (optional)

- Food-safe version (optional)

Elevators

For those who want to aim high! Elevators or belt bucket elevators are continuous conveyors for vertical, dust-free conveying of bulk materials. We manufacture customised elevators as versatile and economical means of transport for continuous conveying. The latest safety components contribute to durability, offering the perfect solution, also available as a food-safe design.

Your advantages at a glance

- Equipped with the latest safety components (speed monitor, misalignment sensors, backstop and full detectors)

- Suitable as a special design for potentially explosive areas

Centre bearing units

We supply split centre bearing units with flexible lamella coupling in stainless steel design, which we have especially developed. The multi-plate coupling compensates for misalignments and minimises trunnion and bearing loads. The centre bearing unit is adapted to the size of the desired screw tube. Integration into existing screw conveyors is possible.

Your advantages at a glance

- Stainless steel split bearing housing

- Split roller bearings

- Cascade arrangement of the screw conveyors is not necessary

- Can be integrated into existing screw conveyors

- Easy to assemble and maintain

- Multi-plate clutch

- Minimum bearing and trunnion load

- Compensation of misalignments

- Air seal connection

- Bearing unit incl. mounting thread with connections

- Food safe design

- Several sealing options: Felt seal, labyrinth seal, shaft seal ring, special food-safe seal

- Permanent lubrication possible

- Screw pipe connection according to customer specification

- Temperature sensor as special design

Contact Person