Performance & Numbers

Our highly trained team and the use of state-of-the-art technology provide us with unsurpassed flexibility. The numbers speak for themselves.

Overview of production capacity

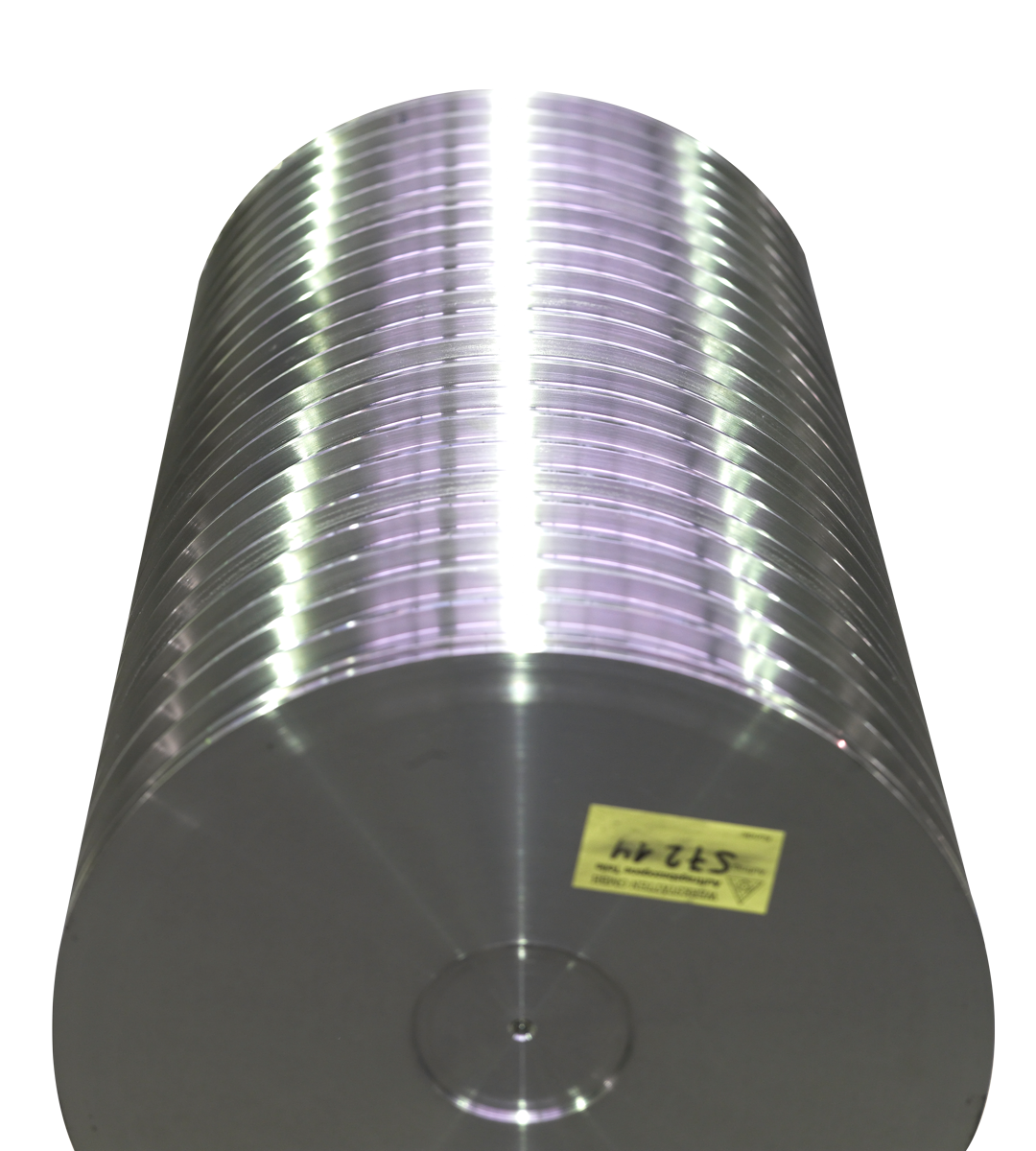

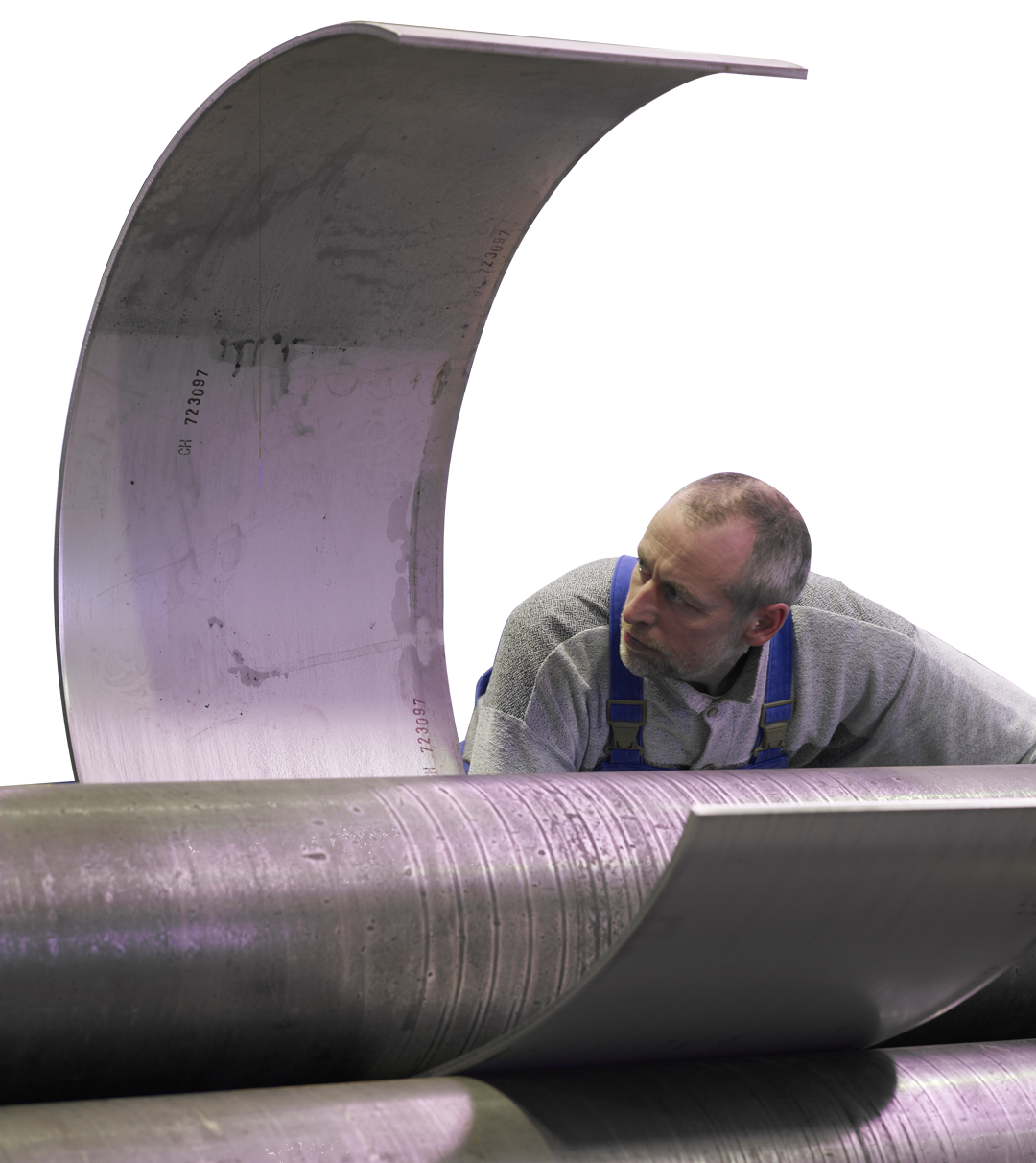

Metalworking & Sheet metal working

- Metalworking & Sheet metal working

- Crane capacities up to 60 t component weight

- Rounds max. ø 5000 mm, max. Width 3000 mm, max. Sheet thickness 20 mm

- Turning man./CNC max. ø 1000 mm

- Length 6000 m

- Milling man./CNC max. 4000 x 1200 x 1500 mm

- Drilling machine man./CNC 3000 x 2000 x 2000 mm

- Blades dynam. ø 1350 mm, max. Length 6000 m

- Profile bending up to approx. ø 114 mm or 100 x 100 mm depending on material and wall thickness

- Edging max. 4000 mm wide pressing force 320 to

- Various welding and assembly workstations with clamping tables, rotary and roller manipulators and rail systems up to a component weight of 60t (learn more)

- Welding methods TIG, MAG, MIG, UP, TIG orbital, plasma taphole, max. System power 1000 amps (learn more)

- Pickling work max. component size 13000 x 5000 x 4000 mm and max. 10 to | Immersion pickling 6000 x 2000 x 1600 mm (learn more)

Processable materials

- Unalloyed and low-alloyed structural steels (e.g. S235, S355 …)

- Fine-grained structural steels (e.g. S275N, S355N,S460, S690QL …)

- Case hardening steels ( 16MnCr5, 18CrNiMo7‑6, C15 …)

- Quenched and tempered steels (C45, 42CrMo4 …)

- Tool steels

- Free cutting steels, (9SMn20, 11SMn30 …)

- High-alloy stainless steels ( 1.4301, 1.4306, 1.4541, 1.4571, 1.4404,1.4529, 1.4539…)

- Duplex steels (1.4462, 1.4410 …)

- Nickel-based alloy (Alloy, Incoloy, Monel, Inconel, Hastelloy, 2,4602, 2.4605 …)

- Casting materials

- Aluminium/titan

- Copper alloys

- Plastics (POM, PE …)

- Special steels (Hardox, Creusabro, Stellite …)

- Heat-resistant steels such as 1.4828, 1.4878

- Cold-hard steels such as P355NL2

Processable materials

- Unalloyed and low-alloyed structural steels (e.g. S235, S355 …)

- Fine-grained structural steels (e.g. S275N, S355N,S460, S690QL …)

- Case hardening steels ( 16MnCr5, 18CrNiMo7‑6, C15 …)

- Quenched and tempered steels (C45, 42CrMo4 …)

- Tool steels

- Free cutting steels, (9SMn20, 11SMn30 …)

- High-alloy stainless steels ( 1.4301, 1.4306, 1.4541, 1.4571, 1.4404,1.4529, 1.4539…)

- Duplex steels (1.4462, 1.4410 …)

- Nickel-based alloy (Alloy, Incoloy, Monel, Inconel, Hastelloy, 2,4602, 2.4605 …)

- Casting materials

- Aluminium/titan

- Copper alloys

- Plastics (POM, PE …)

- Special steels (Hardox, Creusabro, Stellite …)

- Heat-resistant steels such as 1.4828, 1.4878

- Cold-hard steels such as P355NL2

Contact persons