Rotary kiln

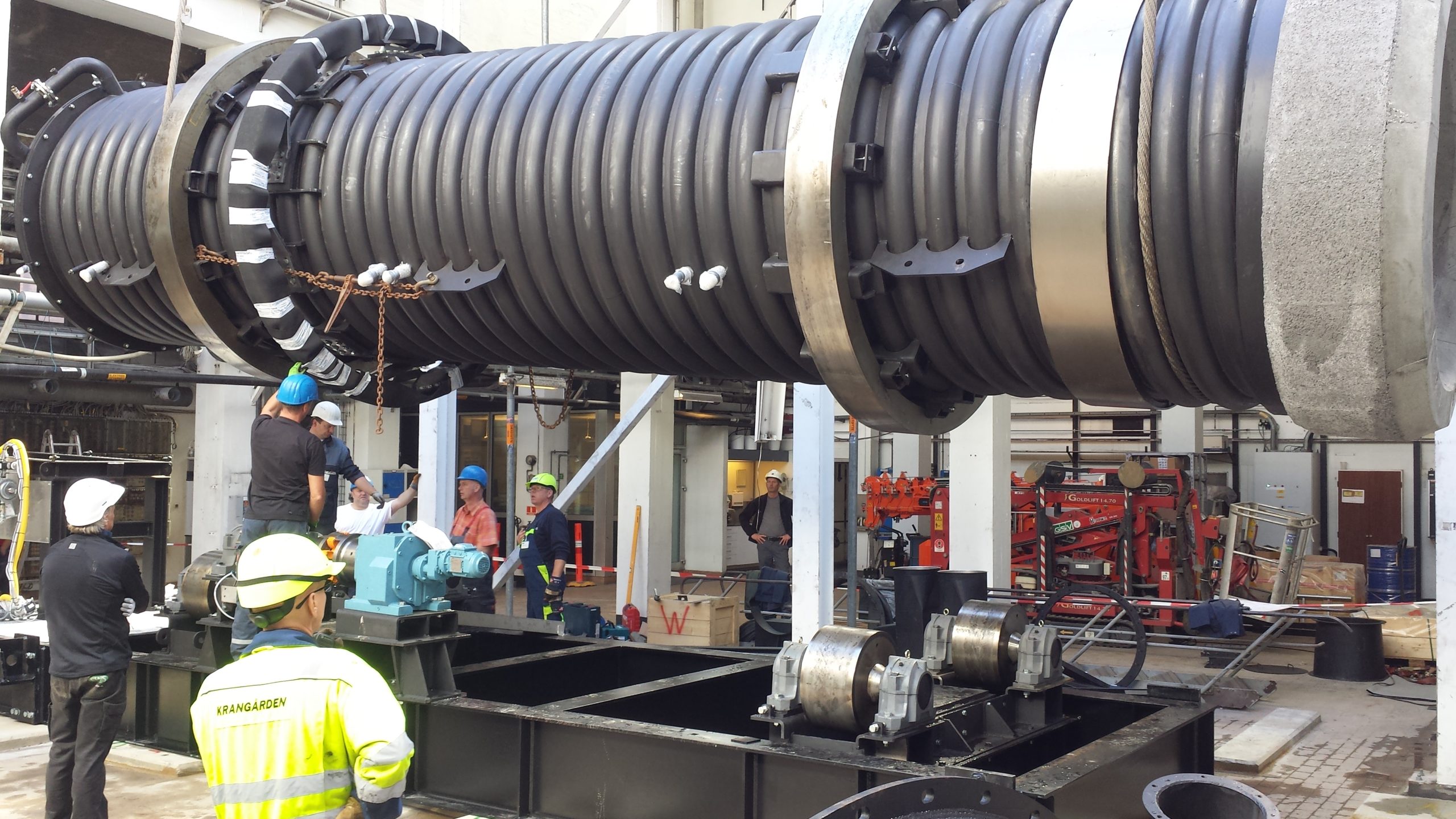

Low-maintenance and reliable in operation, rotary kiln technology enables environmentally friendly energy generation. The potential of this concept deserves to be fully exploited.

Decentralised energy concepts

Agriculture, industry and municipalities are facing increasing pressure to recycle by-products and waste efficiently. We see opportunities above all in the high political and social expectations. Decentralised recycling concepts are increasingly coming to the fore and offer noticeable relief. In order to be able to utilise material flows such as leaves, fermentation residues, seed stock or sewage sludge independently and in a future-proof manner, Werkstätten heating-systems GmbH has developed holistic thermal concepts with rotary kilns. Under the umbrella of the Werkstätten Group, Werkstätten GmbH and Werkstätten heating Systems GmbH participate in the combined experience and expertise. For our customers in the thermal recycling sector, this means maximum efficiency and reliability.

Rotary kilns at a glance:

- Modular design and container solution offer flexibility in terms of location

- Flexible PLC control for regulating the boiler and integrating upstream and downstream components

- Oxygen and load-controlled automatic charging and combustion via dynamic PLC control system

- PLC control with clear visualisation and the option of remote monitoring and manufacturer support

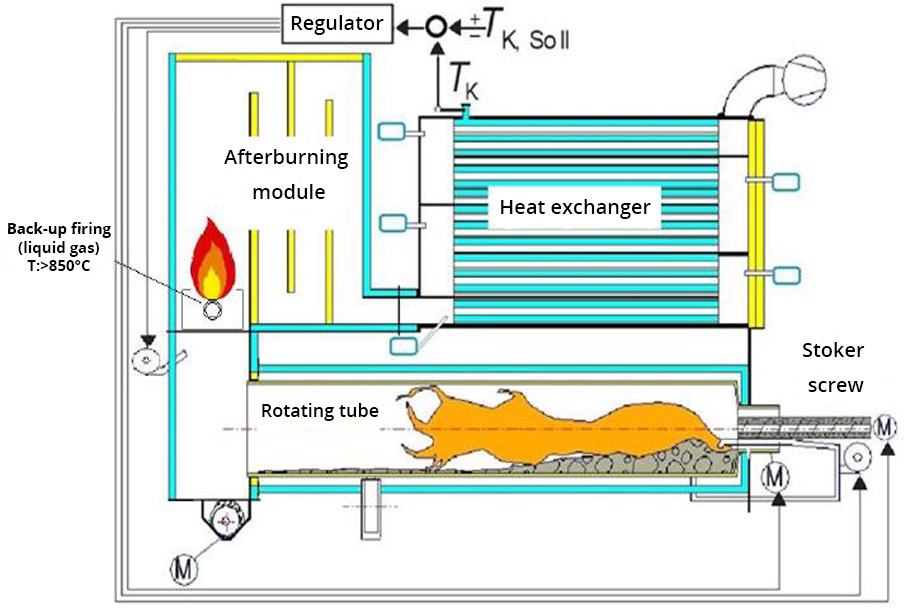

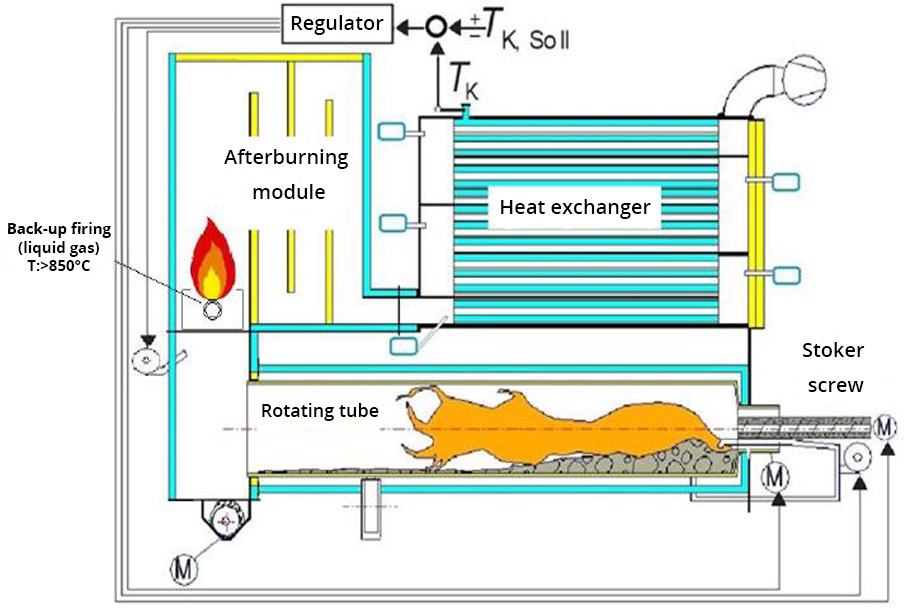

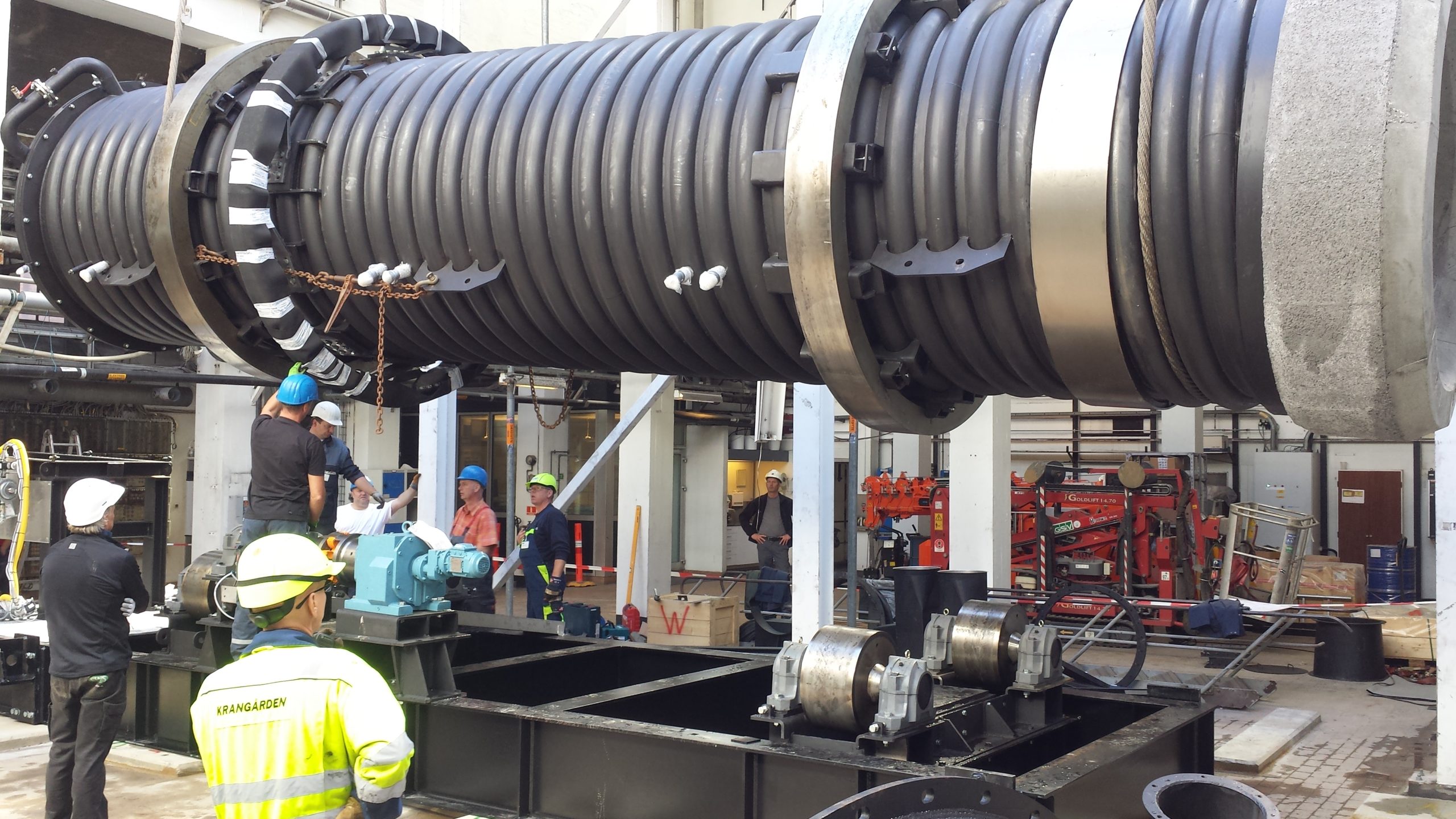

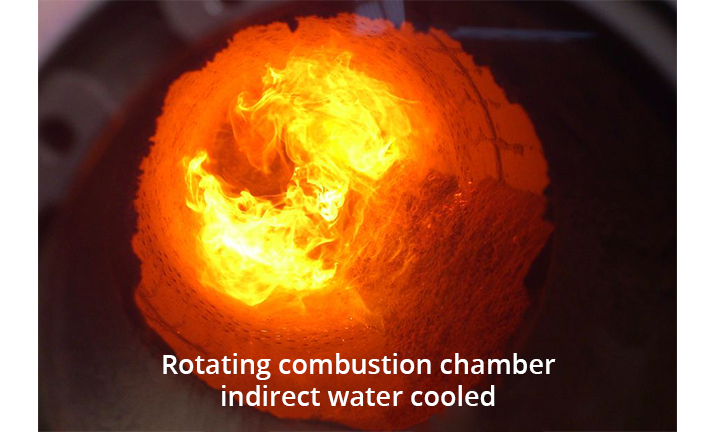

- Water-cooled, rotating combustion zone with divided ventilation zones for supplying fuels with combustion air

- Energetic use of a wide variety of biomasses

- Slag-free combustion of the most difficult fuels

- Very low CO content in the flue gas prevents caking in the heat exchanger

- Almost stoichiometric combustion in innovative rotary kiln

- High efficiency due to constant material circulation

- Automatic ignition

- Automatic ash removal

Rotary kilns at a glance:

- Modular design and container solution offer flexibility in terms of location

- Flexible PLC control for regulating the boiler and integrating upstream and downstream components

- Oxygen and load-controlled automatic charging and combustion via dynamic PLC control system

- PLC control with clear visualisation and the option of remote monitoring and manufacturer support

- Water-cooled, rotating combustion zone with divided

- ventilation zones for supplying fuels with combustion air

- Energetic use of a wide variety of biomasses

- Slag-free combustion of the most difficult fuels

- Very low CO content in the flue gas prevents caking in the heat exchanger

- Almost stoichiometric combustion in innovative rotary kiln

- High efficiency due to constant material circulation

- Automatic ignition

- Automatic ash removal

- Rated heat output: 500 — 5.000 kW

- Partial load: 150 — 1.500 kW

- Approval according to 4th + 17th BlmSchV possible

- Permissible water temperature: 105 °C

- Permissible Thermal oil temperature: 400 °C

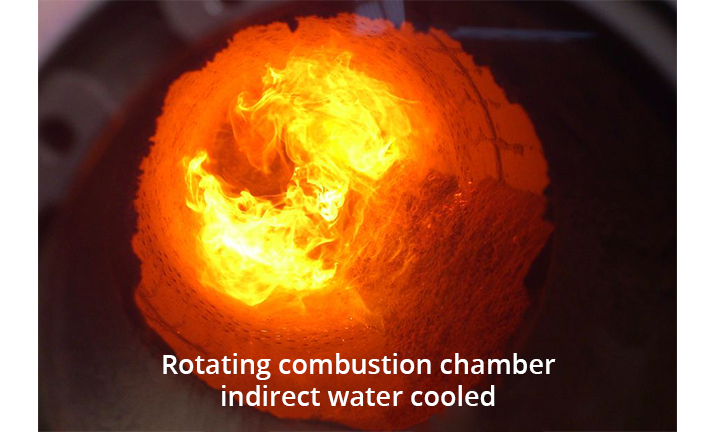

The user-friendly, self-cleaning and fully automatic combustion technology has an innovative, water-cooled rotary tube technology with a number of advantages:

- Suitable for fuels with low ash melting point and high ash content

- Combustion extends over the entire length of the rotating tube with a turbulent flame vortex

- All boiler components exposed to wear and/or high heat loads are lined with refractory and wear-resistant concrete

- In an insulated post-combustion chamber, the flue gases are completely burnt out before they enter the heat exchanger

- Emission values according to the 4th and 17th BImSchV, depending on the fuel, are significantly undercut.

- The powdery ash is low in carbon and free of slag; the nutrient salts it contains are available to plants and can be used as fertiliser Possible forms of energy are

- hot water, steam and/or thermal oil

Examples of decentralised energy concepts

- Digestate drying and incineration for nutrient concentration and mass reduction

- Chicken manure utilisation for heat generation for stables and properties

- Steam generation or thermal oil for industrial and drying plants by using industrial by-products

- Sewage sludge drying and incineration

This combustion technology can use the following biofuels, for example, for energy with a high degree of efficiency and low emissions:

- Landscape maintenance material, screening of woodchips, roadside greenery

- Straw, coffee substitute, seed clippings, nut shells, cherry pits, coffee/cocoa residues

- Digestate from biogas plants, leaves, horse manure, chicken manure

Service

Assembly & Commissioning

An integral part of the large workshop team are experienced and skilled employees who carry out the assembly of products manufactured by us as well as third-party products. We put everything together that belongs together.

Repair & Maintenance

We offer our customers worldwide fast maintenance and repair when required. As an experienced company with technically skilled employees, we solve problems reliably, competently and at fair market prices.

Contact persons

Nils Moggert

Sales Environmental Technology

+49 (0) 5921 / 8076 — 32

n.moggert@werkstaetten-gmbh.de