Quality management

We never compromise on quality. Our quality management has been firmly anchored in our corporate philosophy for decades.

Tested quality

All of the products we manufacture are subject to the same very high quality standards, which are reflected in, among other things, our extensive range of certifications. A strong focus on quality is the cornerstone of our entire corporate philosophy and underpins every move we make. Quality has a tradition and a future with us. We are always working to become even better and even more sustainable. While maintaining our strengths, which we have already demonstrated so often, we go along with and help develop progress further. We are always happy to answer our customers’ questions about our quality management. There is no issue more important to us than quality.

Quality assurance — test procedures

We are experts in non-destructive and precise measurement technology.

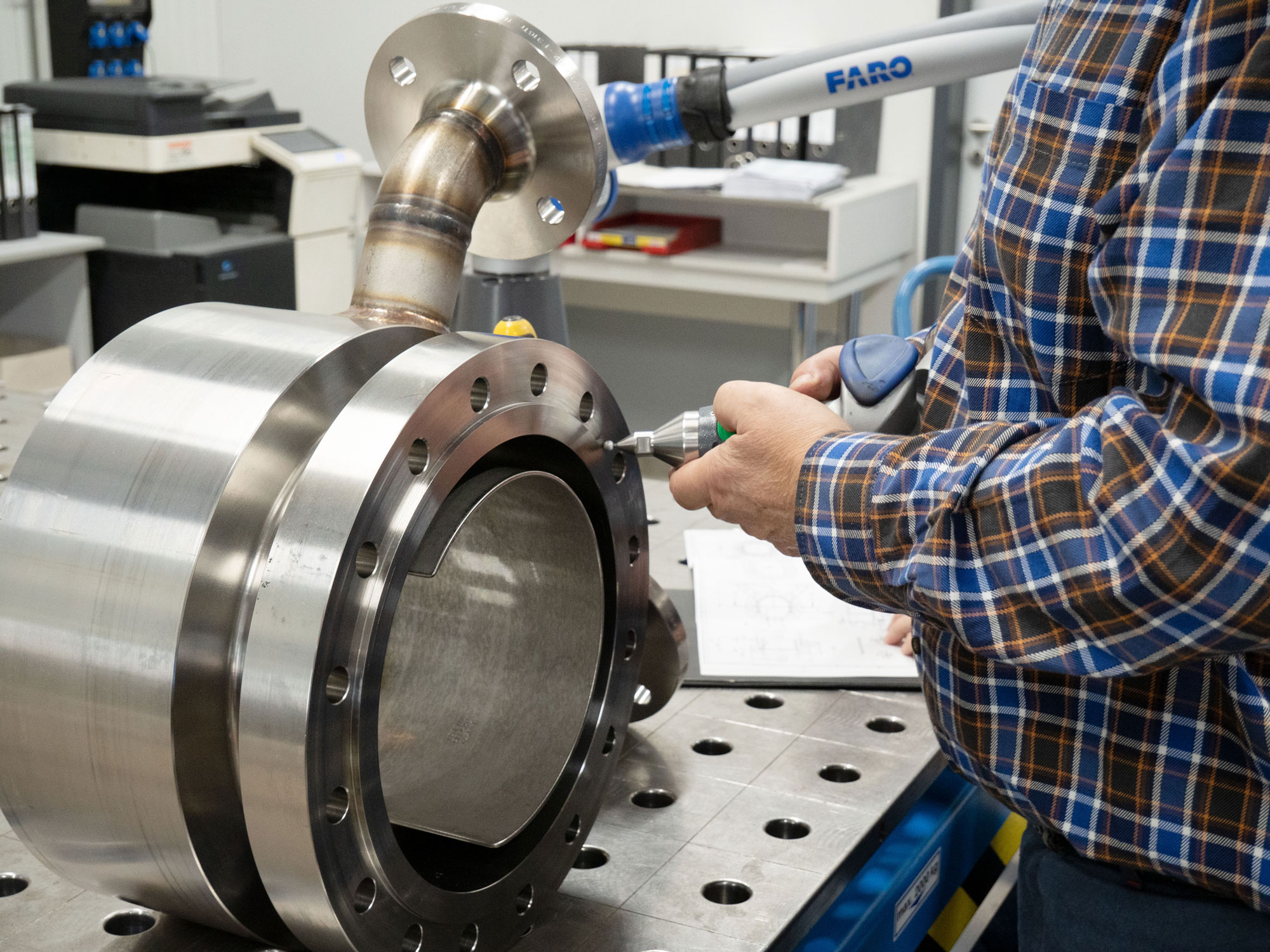

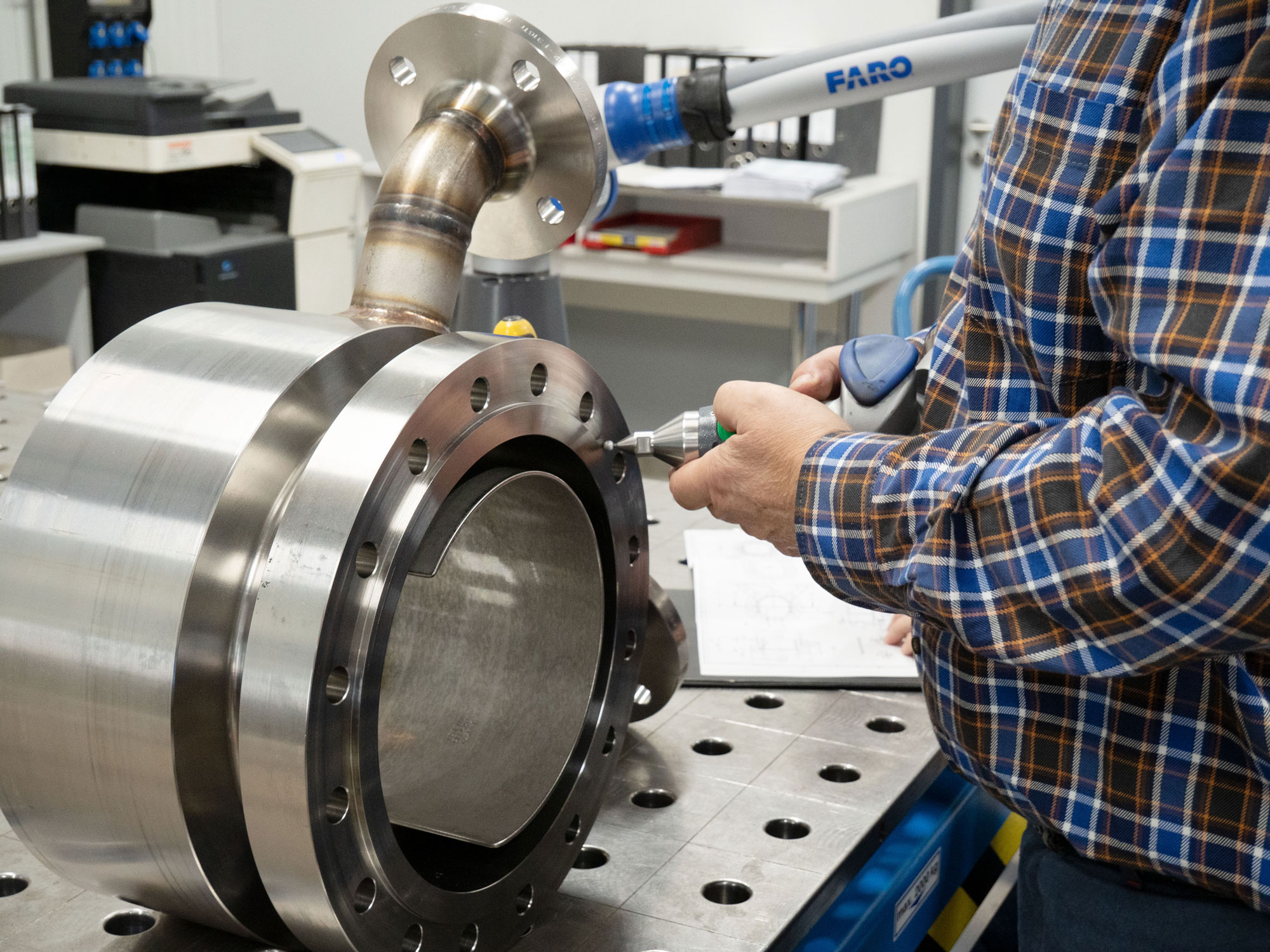

3D measurement

Always accurately tested. In addition to the use of conventional measurement technology, we also apply procedures in the field of 3D measurement technology to ensure quality at the highest level. For example, we use a mobile Faro measuring arm for quality control. Detailed inspection takes place both in the measuring room and on site. All measurement results are logged by internal and external test assignments.

Non-destructive materials testing (NDT)

We have a knack for non-destructive material testing. We test both stationary and mobile. Our main testing procedures include:

- Radiographic testing / X‑ray testing (RT)

- Ultrasonic testing (UT)

- Magnetic particle inspection (MT)

- Dye penetrant inspection (PT)

- Visual inspection (VT)

- Wall thickness measurements

- Vacuum leak detection

“In order to be able to ensure the highest level of quality and performance for both ourselves and our customers, we are continuously working on sustainably improving our products and processes.”

Certificates

The certificates that represent our quality and the high international standard within the Werkstätten Group are clearly listed here:

- Quality management system according to DIN EN ISO 9001:2015

- Certified internal production control according to Pressure Equipment Directive 2014/68/EU

- Certified manufacturer of pressure vessels according to AD 2000 data sheet HP0 — module H/H1

- Certified welding company of pressure vessels according to DIN EN ISO 3834–2

- Manufacture License of Special Equipment PR China for field 1. Pressure Vessels D1, D2 2. Organic Fluid Boilers

- Certified welding company of steel structures according to EN 1090–2, EXC3

- Certified factory production control for building products according to EN 13084–7

- ASME Boiler and Pressure Vessel Code

- ASME U Designator

- ASME R Designator

- ASME S Designator

- Certified specialist company according to the Water Resources Act (WHG)

- SCC**/SCP certified safety management system for technical service providers and personnel service providers

- Certified occupational health and safety management system according to OHSAS 18001

- Certified environmental management system according to DIN EN ISO 14001 — Certified energy management system according to DIN EN ISO 50001

- RAL Quality Mark for “Structural Steelwork”

- Certified manufacturer of boilers for solid fuels according to DIN EN 303–5

Zertifikate

Die Zertifikate, die innerhalb der Werkstätten Group für unsere Qualität und den hohen internationalen Standard sprechen, haben wir hier übersichtlich aufgeführt:

- Qualitätsmanagementsystem nach DIN EN ISO 9001:2015

- Zertifizierte interne Fertigungskontrolle nach Druckgeräterichtlinie 2014/68/EU

- Zertifizierter Hersteller von Druckbehältern nach AD 2000-Merkblatt HP0 – Modul H/H1

- Zertifizierter Schweißbetrieb von Druckbehältern nach DIN EN ISO 3834–2

- Manufacture License of Special Equipment PR China für die Bereiche 1. Pressure Vessels D1, D2 2. Organic Fluid Boilers

- Zertifizierter Schweißbetrieb von Stahltragwerken nach EN 1090–2, EXC3

- Zertifizierte werkseigene Produktionskontrolle für Bauprodukte nach EN 13084–7

ASME Boiler and Pressure Vessel Code

ASME U ‑Designator

ASME R‑Designator

ASME S‑Designator - Zertifizierter Fachbetrieb nach Wasserhaushaltsgesetz (WHG)

- SCC**/SCP zertifiziertes Sicherheitsmanagementsystem für technische Dienstleister und Personaldienstleister

- Zertifiziertes Arbeitsschutzmanagementsystem nach OHSAS 18001

- Zertifiziertes Umweltmanagementsystem nach DIN EN ISO 14001 — Zertifiziertes Energiemanagementsystem nach DIN EN ISO 50001

- RAL-Gütezeichen für „Konstruktiver Stahlbau“

- Zertifizierter Hersteller von Heizkesseln für feste Brennstoffe nach DIN EN 303–5

Contact persons

Ralf Kwiatkowski

Head of Quality Management, Sales Cleaning Systems

+49 (0) 5921 / 8820 — 89

r.kwiatkowski@rosink-werkstaetten.de