Sludge dewatering

Reducing costs and promoting alternative energy generation are goals that we clearly formulate. Sludge dewatering opens up opportunities.

Professional sludge dewatering

Sludge disposal has a significant cost factor. In order to reduce the rising transport, disposal and drying costs from municipal and industrial wastewater treatment and to facilitate alternative energy production, sludge should be dewatered before further treatment or recycling. Using a mobile centrifuge system from Werkstätten GmbH, the volume of sludge produced can be reduced by up to 85%. The high-performance decanters we use can be used both as mobile units and stationary. Thanks to the compact design, the fully equipped units are ready for operation in a very short time after connection to the sludge, water and power supply.

Your advantages

• Complete solution, including modified automotive engineering, from a single source

• Mature technology through years of experience

• Different plant options

• Use of proven individual components

• Stainless steel piping version

• Screws made of stainless steel in proven and robust construction with fully welded gears and bearings on both sides to minimise wear and tear

• Spacious and user-friendly layout of the unit

• Low space requirement of the system during operation

• Free choice of decanter by the customer

• Low set-up costs and quick change of location due to compact design

• Adaptation of the throughput capacity to customer requirements (up to approx. 150 m³/h)

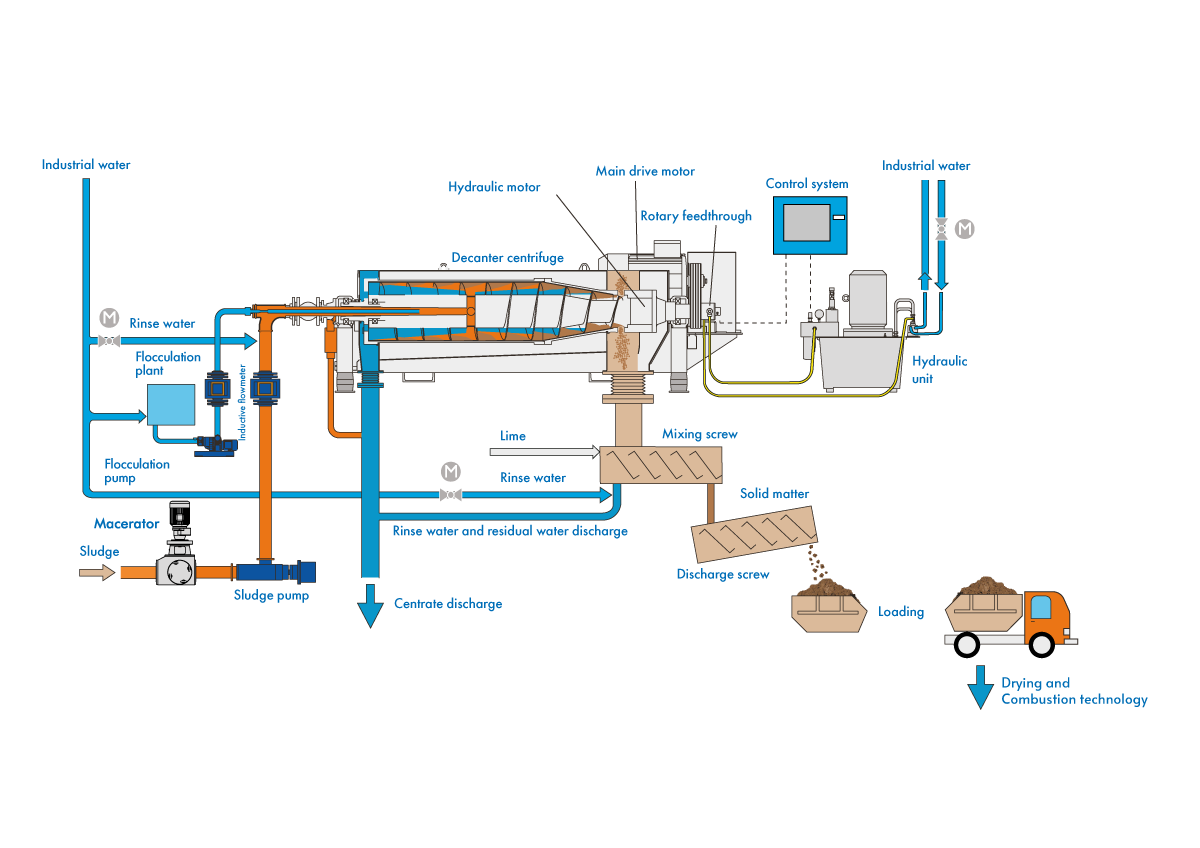

Process sequence of a decanter centrifuge

The sludge, homogenised in advance if possible, is fed to the decanter via an upstream macerator to protect the plant with the help of the built-in sludge pump. A polymer solution is introduced into this product stream — depending on the quantity and nature of the sludge — to promote the flocculation of suspended matter and thus facilitate the subsequent phase separation in the decanter. In the decanter, centrifugal forces are carried out to separate the solid and liquid phases. Water (centrate) and solids leave the machine via separate routes. The centrate drains off via the outlet pipes and can be returned to the clarification process. The solid matter (centrifugate) is conveyed out of the machine by a screw located in the centrifuge drum. If desired, lime can be added to the centrifugate in the mixing screw and then discharged by means of a screw conveyor. This dewatered sludge with a dry matter content of 25 to 30 % can be loaded for further utilisation as bulk material. In addition to the sludge, the purest possible service water and electrical energy are required to operate the plants, which can be generated by a mobile unit if necessary. This makes it possible to use it in almost any place imaginable.

Contact persons