Apparatus & tank construction

The properties of apparatus and containers are always based on the standards and requirements of the respective industrial sector. We implement the individual specifications of our customers.

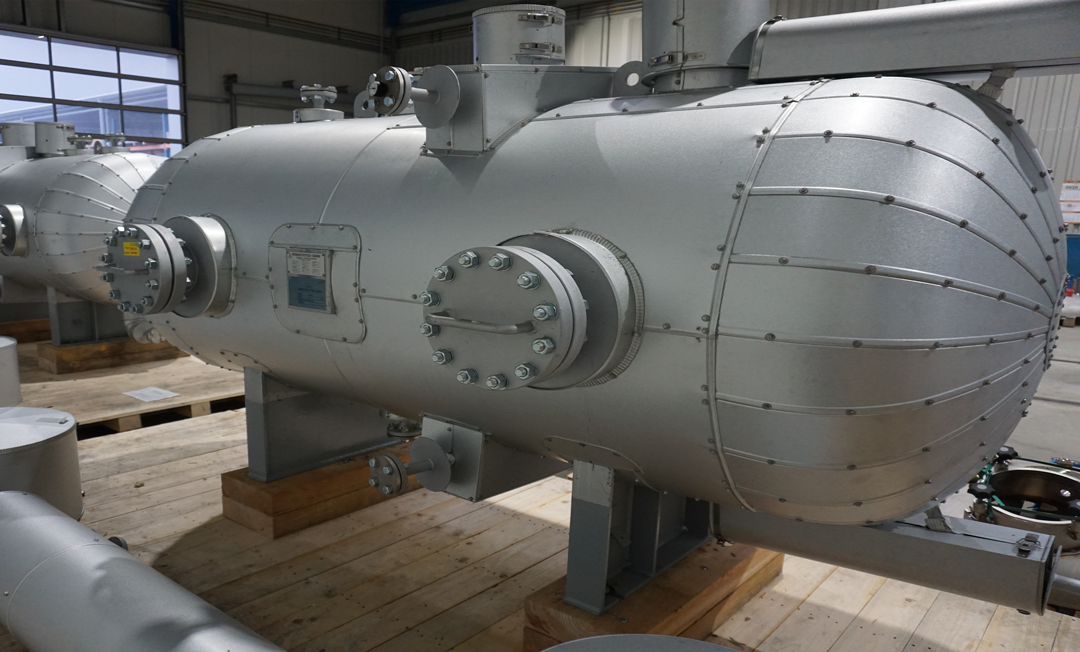

Individual apparatus and tank construction

With our experience and technical equipment, we are able to meet the challenges in apparatus and tank construction in a flexible and solution-oriented manner. In order to ensure the safe and professional use of the apparatus and containers, we comply with the individual specifications, which are inspiration, motivation and obligation for us. We value mutual exchange. The fact that we are allowed to develop suitable solutions for a wide variety of industrial sectors, from chemicals to foodstuffs to energy technology, presents us with great challenges time and again, in apparatus and tank construction. Our experience and expertise in all aspects of stainless steel flow into every project.

Our product range

- Pressure vessels

- Heat exchangers

- Falling film evaporators

- Container construction

- Columns

- Cooling containers

- Vacuum tanks

- Reactors

- Agitator vessels

- Autoclaves

- High-pressure apparatus

- Extractors / Percolators

- Special apparatus

We also manufacture any container accessories that match our portfolio.

Versions and approvals

- Apparatus up to 5m diameter

- Pressure and temperature: Depending on diameter up to

- 250 bar and 650°C

- Design of the pressure vessels according to

- AD 2000, EN 13445 and ASME

- Production and acceptance of pressure vessels according to Directive 2014/68/EU, AD 2000, EN 13445, ASME (U stamp) and China License (Pressure Vessels D1 & D2 / Organic Fluid Boilers)

- Specialist company according to § 19l WHG

- Catch basins with acceptance according to §19I WHG

- Manufacture of construction products for facilities for the storage of water-polluting liquids (marked with Ü sign)

Your advantages at a glance

- FEM calculations | FEM simulations, strength verifications, load change calculation (learn more)

- In-house development & design using HiCAD 3D CAD system

- Preparation of hazard analyses, inventories and budget assessments

- Highly qualified employees

- Modern production facilities

- Expert in-house acceptance by our specialist welding engineers

- Certified quality (learn more)

Our product range

- Pressure vessels

- Heat exchangers

- Falling film evaporators

- Container construction

- Columns

- Cooling containers

- Vacuum tanks

- Reactors

- Agitator vessels

- Autoclaves

- High-pressure apparatus

- Extractors / Percolators

- Special apparatus

We also manufacture any container accessories that match our portfolio.

Versions and approvals

- Apparatus up to 5m diameter

- Pressure and temperature: Depending on diameter up to 250 bar and 650°C

- Design of the pressure vessels according to AD 2000, EN 13445 and ASME

- Production and acceptance of pressure vessels according to Directive 2014/68/EU, AD 2000, EN 13445, ASME (U stamp) and China License (Pressure Vessels D1 & D2 / Organic Fluid Boilers)

- Specialist company according to § 19l WHG

- Catch basins with acceptance according to §19I WHG

- Manufacture of construction products for facilities for the storage of water-polluting liquids (marked with Ü sign)

Your advantages at a glance

- FEM calculations | FEM simulations, strength verifications, load change calculation (learn more)

- In-house development & design using HiCAD 3D CAD system

- Preparation of hazard analyses, inventories and budget assessments

- Highly qualified employees

- Modern production facilities

- Expert in-house acceptance by our specialist welding engineers

- Certified quality (learn more)

- Welding technology & approvals

- Input Materials

- Surface finishing

- Quality

- Areas of application

We use the following welding methods:

- WIG(141) WIG Orbital(141) MAG(135) MIG(131)

- Plasma(151) UP(121) E‑Hand(111)

Welding procedures / welding work are qualified via procedure qualification and welding instruction according to:

AD 2000-HP2/1 ASME Sec. IX DIN EN ISO 15614

Welding work is carried out by certified welders with test certificates according to:

- DIN EN 9606 DIN 14732 (operator certificate)

- ASME Sec. IX AD 2000-HP3

Our focus is on processing stainless steels and higher-grade alloys:

- Stainless steel — austenitic, ferritic and martensitic stainless steels such as: 1.4301, 1.4306, 1.4541, 1.4571, 1.4404,1.4529, 1.4539

- Nickel-based alloy — Alloy, Incoloy, Monel, Inconel, Hastelloy, etc.

- Duplex steels 1.4462 and super duplex 1.4410

- Unalloyed and low-alloyed structural steels e.g. S235, S355

- Fine-grained structural steels e.g. S275N, S355N,S460, S690QL

- Case hardening steels e.g. 16MnCr5, 18CrNiMo7‑6, C15

- Quenched and tempered steels C45, 42CrMo4

- Tool steels

- Free cutting steels, e.g. 9SMn20, 11SMn30

- Casting materials

- Aluminium/titan

- Copper alloys

- Plastics, e.g. POM, PE

- Special steels, e.g. Hardox, Creusabro, Stellite

Pickling work max. component size 13000 x 5000 x 4000 mm and max. 10 to | Immersion pickling 6000 x 2000 x 1600 mm

We can carry out the following test procedures by our in-house personnel:

- Visual inspection

- X‑ray inspection and evaluation

- Dye penetrant inspection

- Ultrasonic testing

- Magnetic particle inspection

- Material identification test

- Inspection via endoscope

Our products are used in the following industries:

- Chemical

- Pharmaceutical industry

- Food

- Bio/environmental technology

- Pulp and paper industry

- Power Plant Technology

- Power Engineering

Service

Assembly & Commissioning

An integral part of the large workshop team are experienced and skilled employees who carry out the assembly of products manufactured by us as well as third-party products. We put everything together that belongs together.

Repair & Maintenance

We offer our customers worldwide fast maintenance and repair when required. As an experienced company with technically skilled employees, we solve problems reliably, competently and at fair market prices.

Examples from the product portfolio

Container construction

We develop products tailored to respective product properties, working conditions and tasks:

- Pressure vessels

- Storage container

- Double walled container

- Multi-level tanks

- Vessels with internal or external heating coils

Columns

We produce individual and customised columns for our customers according to the latest safety guidelines.

These include:

- Distillation columns

- Vacuum columns

- Rectification columns

- Mash columns

- Packing columns

Heat exchangers

We deliver tailor-made solutions for every product and every capacity:

- Falling film evaporators

- Round tube heat exchanger

- U‑tube heat exchanger

- Surface capacitors

- Dephlegmators

- Flue gas heat exchanger

The pipes are welded into the tube sheet using the latest orbital welding technology.

At the customer’s request, the pipes can be additionally rolled in to prevent crevice corrosion.

Stirring tanks / stirrers

We manufacture agitator vessels with pillow plates or half-pipe coils according to customer requirements.

Pre-installation of agitators is carried out in close cooperation with the selected agitator manufacturer.

Autoclaves — special containers

Quality-Made in Germany. We use our experience and know-how, which has grown over decades, to manufacture suitable special containers for a wide range of industries.

Our customers benefit from our certified quality, which is guaranteed by our highly qualified employees. We have the most modern production facilities and maintain a constructive exchange with our customers. Every special container that leaves our halls contains real expertise.

Autoclaves — special containers

Quality-Made in Germany. We use our experience and know-how, which has grown over decades, to manufacture suitable special containers for a wide range of industries.

Our customers benefit from our certified quality, which is guaranteed by our highly qualified employees. We have the most modern production facilities and maintain a constructive exchange with our customers. Every special container that leaves our halls contains real expertise.

Contact persons

Reinhard Krull

Sales Manager Apparatus Construction